PLC Profibus

Basic Info.

| Model NO. | CD |

| Transport Package | According to Customer′s Required |

| Origin | China |

| HS Code | 853710119 |

| Production Capacity | 10000PCS/Year |

Product Description

PLC PROFIBUS-DP Slave station extension module Programmable Logic Controller

Based on research and development servo system,we independently developed this PLC.Grate advantage of price and quality.More convenient to supply complete servo control system.

Programming is more convenient:

Add C language function programming method.

C language screen.

Add C language function interface.

Editing interface of C language function.

Support most instruction & ladder diagram and instruction list programming of PLC.

Increase the C language function programming mode to make the control function more simplified and precision.

Users can programming the function module themselves if needed.

Professional synchronous control:

High-speed pulse output, pulse frequency can up to 250KHZ

Support pulse output function and high-speed counting function, the maximum pulse frequency can reach to 250KHZ

Add S-type acceleration/deceleration commands, arbitrary curves, and control functions for relative positioning and absolute positioning commands.

Make motion control more precise and stable.

S type acceleration and deceleration curve.

Arbitrary curve.

Absolute positioning and relative positioning curve.

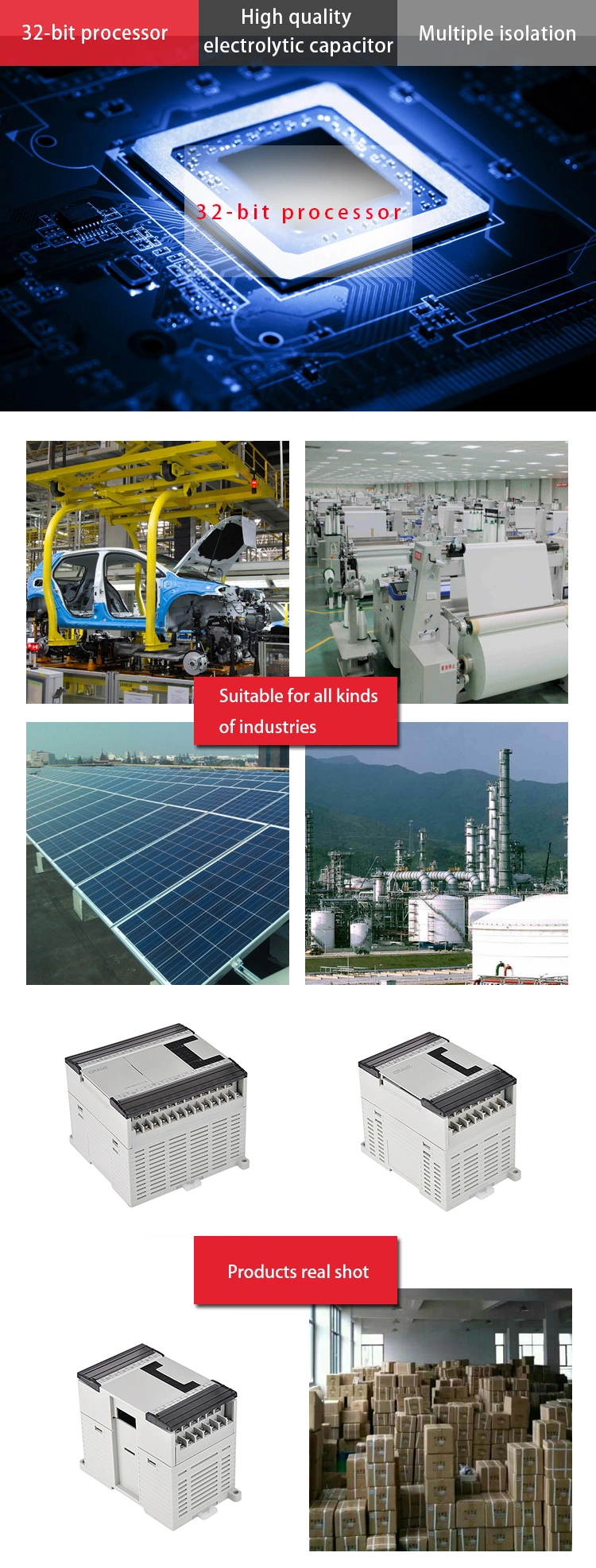

Suitable for all kinds of industries.

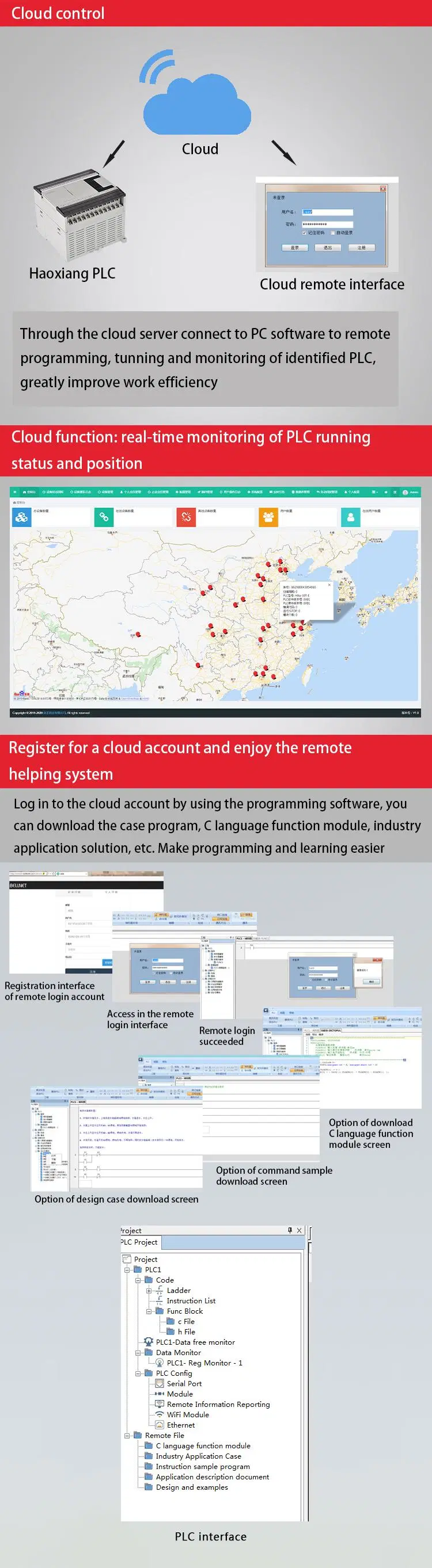

Register for a cloud account and enjoy the remote helping system.

Log in to the cloud account by using the programming software, you can download the case program, C language function module, industry application solution, etc. Make programming and learning easier.

Registration interface of remote login account.

Self-developed PC programming software, similar as Mitsubishi series programming. High improve convenience and comfort of programming.

High programming convenience and comfort.

32-bit processor.

High quality electrolytic capacitor.

Multiple isolation.

through the cloud server connect to PC software to remote programming, tunning and monitoring of identified PLC,

greatly improve work efficiency.